Structural sheathing is typically cut slightly short of 48 inches by 96 inches to allow for this expansion gap look for a label that says sized for spacing.

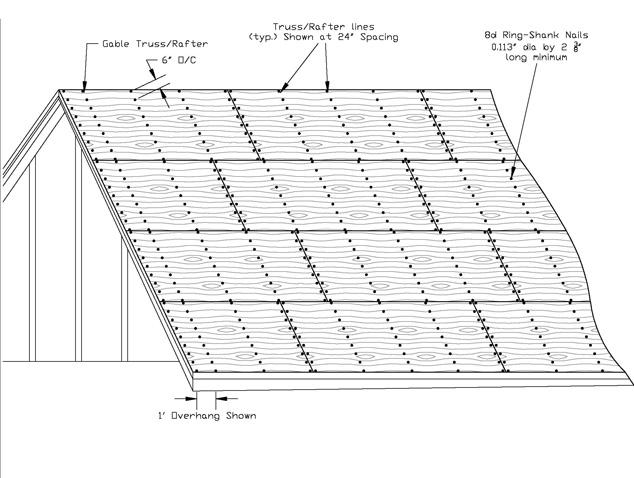

Nail spacing for roof sheathing.

To assure best performance follow these panel spacing and nailing recommendations for apa rated sheathing apa rated sturd i floor and apa rated siding.

Unless otherwise indi cated by the panel manufacturer leave a 1 8 inch gap about the width of a 16d common nail between panel edges to allow for expansion.

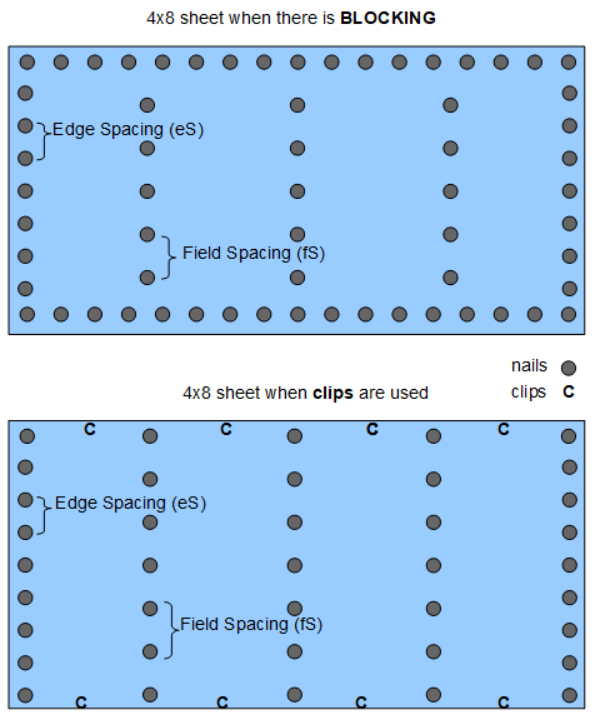

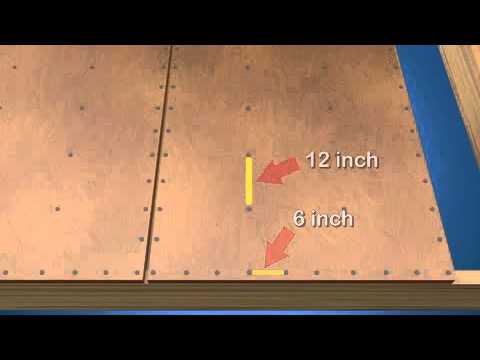

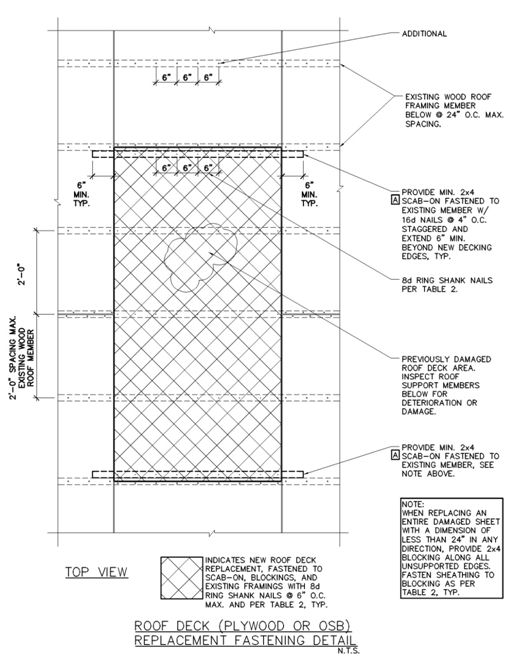

Nail spacing is recommended 4 inches on center maximum.

There are typically 12 16 or.

The type of nails you ll need to use during the sheathing process depends on the roof material thickness.

Check the nailing surface is level step 2.

Spacer type panel edge clips may also be used for roof sheathing applications.

Properly fasten panels including fastening and spacing hints step 4.

Roof truss spacing will vary on the structure s construction.

Method for maintaining a continuous load path at the roof ridge by nailing roof sheathing.

Ventilate the roof according to current building codes step 3.

Use a 10d box nail to gauge 1 8 inch spacing between panels.

How many nails per board in roof sheathing.

Cover sheathing with.

And scroll down to see more details on each with installation hints and tips below.

Holes drilled in roof sheathing for ventilation roof diaphragm action is maintained.

For clarity sheathing nails are not shown ladder framing at gable ends.

Click to expand contents.